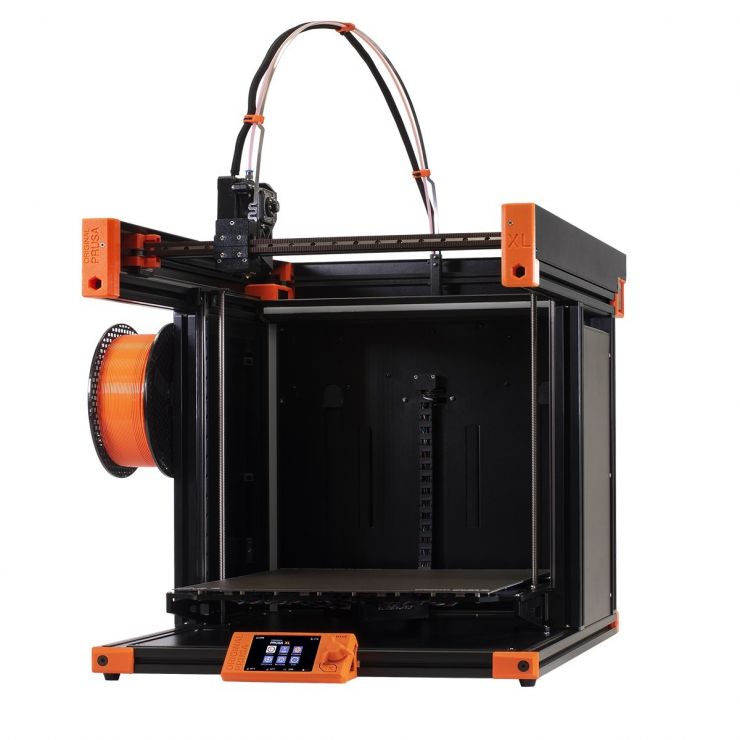

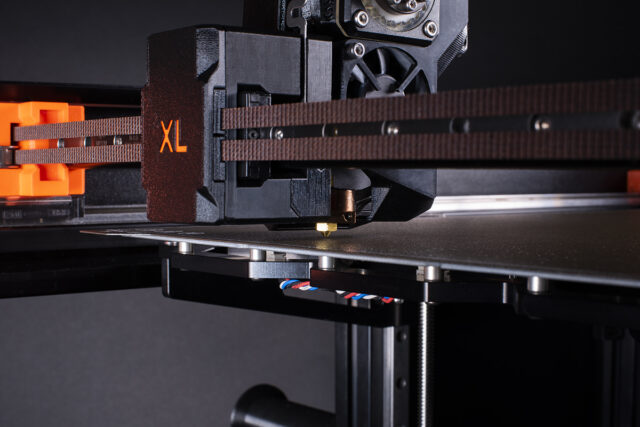

This past week, Prusa announced a new model, the Original Prusa XL. [author's sidenote: I don’t know why they put “Original” in front of the name since it’s not even out yet. My only theory is that they traveled into the future to a point where an upgraded version exists, and the new Prusa XL, which is their old Prusa XL, got branded as “the Original Prusa XL”, to differentiate it from their other Prusa XL (which would be current for them, but for us it is so new it does not yet exist.) And so they took an “Original Prusa XL”, but forgot to delete “Original” from the branding...perhaps due to mental fatigue brought on by time travel. In any case, I don’t want to write “Original” any more, so for this article, I’m just calling it the Prusa XL.] Prusa's I3 MK2 printer set the standard and popularized the style of FDM printers that are most used today so based on the name, I expected them to stick with their known winning formula and add a larger print area. I was really surprised to see that they made a ton of real, significant changes from their previous designs. There is almost no component on it that isn't a unique improvement over all the other printers out there (including their previous Prusa models). But progress has a price, and that price falls between $2,000 USD (basic and unassembled) and $4,000 USD (loaded and assembled). It's official release is scheduled for mid to late 2022 as well, so there's time to start saving your pennies, or put a swear jar by your current printer if you want to save up for when this new model comes out. But I'm a tinkerer (and I'm kinda cheap) so this level of luxury and convenience (yeah, and price) takes away a lot of the interaction that I enjoy in the first place.

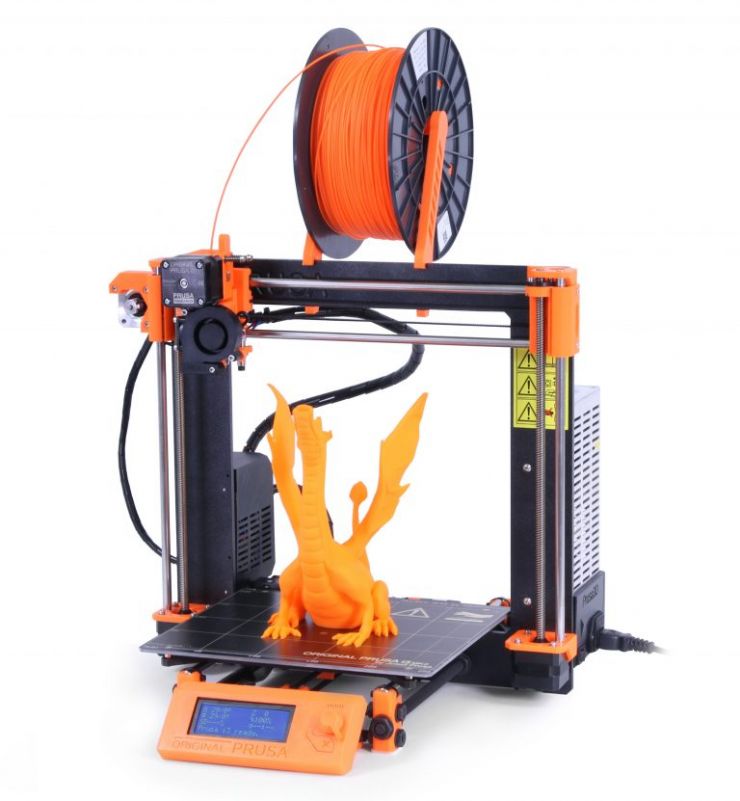

The legendary Prusa I3 MK2 - the inspiration for most current consumer printers

I don't see a Prusa XL in my future, but it has SO many innovative pieces that I thought it might be worth talking about. And since you can't talk about what's new unless you understand what's old, I thought I could take this opportunity to work in a compare/contrast introduction/discussion to some of the components on 3D printers, so even if you know nothing about how 3D printers work, you can still walk away saying “ah, that IS cool.” As I said earlier, in a comparison with pretty much any consumer printer, the Prusa XL’s features objectively win almost every category except speed and price so this is not a contest and I’m not writing to put other printers down. I'm just comparing what makes this printer unique with the things other printers are already doing.

Size : It's not surprising that the Prusa XL is bigger than the average printer. The most common printer models can build something that is 220mm x 220mm x 250mm (about an 8" cube, give or take). The largest consumer printers I have seen can basically double that. The Prusa XL can print 360mm x 360mm x 360mm, (about a 14" cube). Not the biggest out there, but big enough for almost every home-grown print project.

These are just some of the big points I found worthwhile to mention, but they really did some great stuff here and I'm glad Prusa has been busy moving forward and continuing to innovate in the printing industry. Even though all these features are more or less exclusive to the Prusa XL at the moment, It’s easy to see how elements of these features could be used to improve printers of every size, style, and budget. I look forward to seeing what else Prusa may come up with in the future, but I’m honestly more excited about the inspiration these features can give the community (because the 3D printing community can replicate and improve things at an incredible pace.) Prusa just took some interesting first steps, so what other steps can people in the printing community see now? Maybe an open source system that takes the multiple modular extruder idea and makes it an add-on for regular printers so people like me can easily run multi-material prints. Or if we can have a 4x4 heating grid, why not a 1024x1024 heated grid? (If you take that idea and run with it and it works, buy me lunch or something, ok?)

If you want to see the official product listing and/or pre-order an Original Prusa XL, click here.